Directly to ...

Motivation and background

Reservoir model description

Problem statement

Reservoir model files description

Timeline

Support

Frequently Asked Questions

Optimization Challenge download files

Optimization Challenge

Frequently Asked Questions (last update 15 February 2018)

- Can I use any reservoir simulator for the OLYMPUS challenge? Yes, Participants are allowed to use any simulator they would like to use for the Olympus Field Development Optimization Challenge.

- If I use a different reservoir simulator what must be checked? If you use a different simulator please confirm the production responses as provided with the ECLIPSE input files to ensure close/similar production responses.

- Is there any limitation on the type of optimization methods which can be used? No, there is no limitation on the type of optimization method. Participants are encouraged to use any method they deem useful.

- Must we complete all the exercises for the challenge as described on the website and in the problem statement document? Participants are highly encouraged to complete all these exercises as listed on our webpages and in the problem statement document.

- Must all the 50 realizations be used during the optimization process? Participants are free to use any number of realizations during the optimization process. However, the final optimal strategies must be evaluated over the entire ensemble of model realizations.

- Can we use reduced order or simplified models for the optimization process? Yes, participants can use any form of proxy or reduced order models. However, the final optimal strategies must be evaluated over the entire ensemble of model realizations provided.

- Can we use a modified/simplified economic model or relaxed constraints for the optimization and evaluation of the results? Participants must use the economic model as provided, whereas all field production constraints must also be strictly adhered too.

- Are the models provided history matched? No, the models provided have not been history matched. OLYMPUS has only been recently discovered and is in the field development planning stage and therefore no production data is available.

- Can we generate data after a few years of production for history matching and then optimize for the remaining time period? No, participants are not allowed to do any kind of history matching. The purpose of this challenge is Field Development Optimization of the OLYMPUS field.

- How will the results be compared and evaluated? TNO is working on creating a format for participants to submit their results and which will be used for comparison purposes only. This format will be launched on via our webpages in due course.

- When and where will the final results workshop be held? All details on this are found via the timeline web page for the challenge.

- Why has a full closed loop reservoir management (history matching + optimization) challenge not been initiated instead of an only optimization challenge? This challenge was formulated together with many experts from industry and academia who work in the area of closed loop reservoir management. Since the first step in developing any oil field is to develop an initial development plan it was decided to pursue this aspect for this challenge. A follow up challenge, the idea of which is already being toyed with, would include history matching i.e. performing a full closed loop reservoir management exercise. However, the only logical step from the viewpoint of processes and workflows which companies undertake on a daily basis is to first do a field development optimization challenge. Thus history matching is not included in this challenge and participants are not allowed to update their models. One important aspect of this challenge is to compare algorithms and workflows that participants use on the same set of models so that comparisons are possible. Please know that a full closed loop exercise challenge has already been undertaken in 2008 and which is now known as the Brugge Case Study. There are a lot of papers and information about the results from the Brugge Case study already available online.

-

For the second part, field development optimization, should we remove all the existing wells? If no, should we change the control model to BHP with max and min and apply the reactive strategy? You are free to choose what you decide to do for the second optimization exercise. You do not need to use any of the wells provided. The wells provided are only essential for the well control optimization problem. Regarding your second question at this stage, the wells are controlled by BHP control and we would like to keep that for the field development with constant values i.e. max and min throughout.

-

In the project proposal says that ICV wells can be used for the well control optimization challenge. Related to this I have the following two questions:

1-Is there a maximum number of valves that can be used in a well?

2-Is there a cost to implement a valve?

Based on feedback from many participants and even more accurate concerns about the capabilities of different simulators to properly model ICV's we have decided not to allow the participants to pursue the ICV controls. So these questions are no longer relevant.

-

Theoretically, when we apply reactive control to determine wells shut-in time, the well is shut after half of the field's life time so that the uncertainties have already been reduced and we have a better idea of which scenario best represents the field. Considering this I have the following question: Could I create one reactive strategy for each set of similar scenarios rather than a single reactive strategy for all scenarios? Not sure whether to agree with your reasoning for reactive control. From our limited field experience, and based on feedback from a variety of different operators, reactive control is applied when the water cut reaches the economic limit irrespective of the time in the life cycle period. Since we are primarily focused on field development optimization in this challenge, reducing uncertainties either through history matching or other methods is out of the scope of this exercise. With this being said it could be that we have misunderstood your question. If that is the case please get back to us.

-

It has been stated “The liquid processing capacity of the platform facilities limits the field production rate”. And in Table 3, the Max. platform liquid production rate is 20000. Is this limit per platform? If so, since there is no limit on number of platform, can I assumed that if I decide to set up 2 platform, my max. field liquid production rate could be 20000*2=40000 bbl/day? Yes, if you have a second or third platform then you can produce even more. However, your costs increase as well. So, if you find such a strategy to be optimal then that is allowed.

-

What is the life-cycle period at which NPV should be provided? 20 years is the life cycle period. Thus, all results should be generated for a 20 year time horizon. NPV is further defined in the problem statement document.

-

Is the subsurface uncertainty fully contained within the 50 realizations, or would you expect those realizations to be further modified with uncertainties? Either porosity/permeability modifiers, or dynamic data such as rel. perm tables. Or maybe fault/barrier modifications? In simple terms, at present we have 50 realizations, which can be regarded as discrete or categorical. Should we also include further continuous modifiers in the subsurface uncertainties? The ensemble of models provided should not be modified in any which way. The purpose of this optimization challenge is that everyone uses the same set of models. Thus, no changes to the model are allowed.

-

Is there any uncertainty in initial conditions? We do not provide explicit pressure and saturation files at the initial state for the realizations. The models are initialized using the standard equilibration option in ECLIPSE.

-

In the well control optimization exercise, can we assume that the optimization will have to decide, for each of the wells, whether they are a producer or injector? I assume they cannot switch during the 20 years. For the well control exercise the injector and producer wells have already been provided in the input decks and those cannot change i.e. be switched during the life-cycle period. Participants are free to decide if they optimize rates, pressures, single well PI multiplier (for the entire well), etc. in these wells. This is the freedom participants have for the well control exercise.

-

For the field development optimization challenge, do wells have a single perforation? No, wells can have multiple perforations. Participants can decide on the number of perforations. We think that when you drill a vertical or horizontal well you would want to make multiple perforations especially for a reservoir model like OLYMPUS. Unless you deem it optimal to have a single perforation. There is no restriction as such on the number of perforations.

-

You state in the well control optimization that for 18 wells, 20 years, 3 month intervals, there are 18x20x4 = 1440 controls. So, this implies one control device per well. Hence my question on the number of perforations/completions. Could a single well penetrate multiple layers/zones, and have multiple control devices and multiple completions? I guess my question, in more general terms, is what kinds of completions and well designs are allowed? This can, of course, rapidly increase the number of controls, and introduces integer or binary variables. The calculation of the number of controls is purely as an example to say that those would be the maximum number of controls if a participant controls only a single variable per well since the minimum control time interval is 3 months. Participants are not allowed to use control time intervals of less than 3 months but can certainly use larger control time intervals in multiples of 3 months.

-

For each of the exercises, should optimization be performed under subsurface uncertainty, or should optimization be performed separately for each of the 50 realizations, or should optimization be performed for a single chosen realization? I am familiar with the problem of optimization under uncertainty, but it should be absolutely clear what we are attempting to do. Moreover, the issue of how to present the results of optimization under uncertainty may have differing views - it is certainly not a question of finding the maximum NPV. Every participant is free to decide how to perform the optimization experiments. However, results i.e. objective function must and will be compared as the mean value of the objective function over the ensemble of 50 realizations irrespective if a participant uses the full ensemble during optimization or not. The objective function defined in the documents is expressed as the mean NPV over all the realizations.

-

I assume the 50 realizations are equiprobable? Can other objective functions be used to perform the robust optimization experiments? Yes, all realizations are equiprobable. After consultations with a wide array of people from academia and industry we have defined the objective function to be the mean over the ensemble. Participants are always encouraged to present as detailed results as possible. Other objective functions can also be chosen to account for risk measures and participants are free to do more than what is defined in the problem statement. However, they must do at least what is defined in the problem statement.

-

Can we assume that the problem statement is completely open? The problem statement defines the scope of the problem. So, the problem is not completely open. Participants must adhere to the problem defined as well as the bounds and constraints described in the problem statement document as well as use the economic model provided in the documents.

-

What latitude is there in the type of ICV? I have done optimization under uncertainty in a complex case, looking at many aspects but including choosing between SAS, PICD, AICD or ICV. Based on feedback from participants, ICV or any other types of devices as mentioned in the question are not allowed to be optimized. Participants can optimize a single PI multiplier of a well over time.

-

I am a little surprised you are not including any dynamic modelling changes, it would have been easy to define these so that all participants are doing the same thing. Including dynamic modeling changes is something which was considered by us and discussed with a larger audience from various universities and companies. It was thereafter concluded that this aspect shall not be included this time, however maybe another time in a future edition of this optimization challenge.

-

In the challenge exercise 2 (Field Development Optimization), 'Drilling of each next well is started immediately after finishing the previous one’, does this mean there is only one drilling rig available each time? Can we drill more than 1 well simultaneously? We have one drilling rig from which only one well can be drilled at a time. So, two wells cannot be drilled simultaneously. What this specific sentence was intended to reflect is that you do not need to wait a minimum number of days before drilling another well to for instance move the rig to a different location.

-

Would you please clarify on the use of zone/connection controls? We do not provide any zonation information. So for the exercises and thereby deliverables for this challenge we do not use any zonation/connection controls. This is outside of the scope of the challenge.

-

Is it allowed to use smart completions with ICVs to choke separate perforation intervals? No, it is not allowed to use ICV’s to choke separate perforation intervals. This is outside of the scope of the challenge.

-

What about assigning economical limits to connections on reaching which they are to shut or other workover to happen? We do not encourage assigning economical limits to connections as we see that to be reactive control. However, if you decide to use them within an optimization then you will have to use the economical water cut value (our rough calculation is an economic WCT of 88%) which you can calculate based on the NPV model provided. Since we do not provide workover costs, we assume a connection cannot be worked over though and can be reopened without any workover. Workover operations such as reperforating, converting producers to injections are simply not allowed as part of this challenge.

-

In the challenge's exercise 2 (Field Development Optimization), should we remove all wells provided and starting field planning from a totally green field, or should we drill infill wells besides the existing wells? For exercise 2 you are free decide how to proceed. Thus, you are well within the scope of the problem to treat this purely as a green field and then decide through optimization the entire plan including, location, number and type of wells. If you think it is better to drill in-fill wells that is also within the scope. However, the way we envisage the problem is that participants start as if it is a green field.

-

In the last line of the Proposed Scope (Motivation and Background), 'The risk associated with uncertainty' was mentioned, will there be a clear definition on how the decision risks will be measured if we deliver results for this competition? No, we do not provide risk measures for optimization. The sentence was intended to reflect a larger point without necessarily being included in the problem statement.

-

Is it allowed to convert producers into injectors (for example, when well produces with high watercut)? No.

-

Are there any constraints on platform injection capacity? These are specified in the documentation.

-

There is one sentence above the equation of R(t_i) saying platform investment cost must be introduced in the first month of the first well, but the paragraph below indicates 'Production platform investments cost are ... included in the cost per drilled well.' I suspect this latter 'Production platform investment' indicates a different cost (the maintenance cost for each well) which is negligible? The platform cost is included at the start date, whereas the drilling costs for wells are included when a well is drilled.

-

Could you clarify what the terms are to participate? Not sure what exact clarifications you would like to get information about. We are distributing the OLYMPUS models for free and will organize a results workshop in September 2018. Attendance to this workshop will probably come with a registration fee for each participant.

-

How will differences in simulator capabilities by mitigated? This is a very important point and very difficult to answer. If you have an idea on how to regulate this aspect we would be happy to know. The results workshop will provide a platform to discuss and debate such matters.

-

How will differences in computational capabilities and simulator license availability be mitigated? Participants will have to manage their own computational capabilities and simulator license availability issues. With the availability of open source simulators for which we have benchmarked the models this aspect should not be a problem for participants. For now we have not yet had any complaints about this from the 30+ participants who registered for participation.

-

What is your opinion on valuing the cost of simple versus complex development plans? This was certainly considered and after discussions with members of the smart fields community spanning academia and industry it was decided to not include this aspect in this current optimization challenge. Will certainly be a point to be considered for future optimization challenges.

-

Do you plan to provide a utility function? No, we do not plan to provide a utility function. We will use the expected value of the objective function over the ensemble of models as a metric for comparison. This was done after discussions with a larger audience of the smart field community from industry and academia. However, please note that participants are free to pursue additional experiments as long as they provide solutions to the experiments detailed in the problem statement.

-

Benchmark or challenge? This is more of a challenge than a benchmark as there is no “correct” or “known” solution. For the well control optimization exercise which is intentionally designed to be more restricted in problem scope we hope that we can also benchmark methodologies/workflows used by participants.

-

Can you clarify what “history matching” means in the context of this challenge? In this challenge, we do not provide participants with data which can be used to update the ensemble of models (which we refer to as history matching in the FAQ section). Thus, participants must use the provided set of ensemble of reservoir models. If participants want to build proxies for the optimization then they are free to do so using the ensemble of models provide without changing the properties of the provided models. Please note that the results will be evaluated on the ensemble of high-fidelity models provided and not on the proxy models used.

-

Restrict to a single open source simulator. Our objective is to allow for variability in workflows which includes variability in simulators and optimization algorithms. Thus, we will not restrict participants to a single simulator.

-

Create classes of solutions, e.g. with/without ICD, with/without EOR techniques. Defining classes of solutions is also something which was discussed and was decided to set out the broad contours of the problem (as has been done thus far) and generate feedback since it is impossible to consult everyone before such a challenge is launched. Now that we have obtained suggestions from a variety of participants we have modified the problem definition to accommodate the capabilities of all participants and standardize the challenge as much as possible. No ICD/ICV or EOR techniques are allowed, it is only water flooding optimization.

-

Provide a representative problem which does not require a simulator? This is not something we will consider as all operator companies who provided input during the set-up of the challenge wanted realistic (representative of field scenarios) simulation models to be used.

- Is it possible to get the OLYMPUS field as a Petrel project? We have received many requests to get access to the Petrel files, but for a variety of reasons we do not to release the Petrel project to any of the participants.

- Could you share with us the well trajectories of the Olympus project? As for the question under number 50, we do not provide this additional information to participants on the Olympus Optimization challenge.

-

The document says that "participants are also free to decide the controls (rates, pressures, single well PI multiplier etc.) they aim to optimize, but where multiple ICV controls along the wells are not allowed" Can you confirm if we are allowed to use PI multipliers on number of connections in order to control the downhole rate (i.e zonal rate control) rather than well rate. We intend to allow only a single well PI multiplier as is specified in the document. Zonal control is not allowed as that becomes akin to having ICV/ICD’s depending on the modeling and definition which varies throughout the industry.

- In well control optimisation problem, how can we have well liquid constraint of 5700 bbl/d and field liquid constraint of 88,000 bbl/d with only 11 producers. Since (11x5700=62700) , it seems that the field liquid constraint is redundant. If this is the case, the optimisation may not show much value, I expect. I mean if you have well maximum rate constraint of 5700 and even no downhole control, then I assume the best control would be to produce from all wells with maximum rate until each well reaches to maximum economic WC and then shut it. Would you please advise if I am missing any point here? Thanks for pointing this out, it should have read “maximum well oil production rate” instead of “liquid”. This will be updated in the documents as well. This is provided incase someone decides to use rates as controls instead of say BHP as the control.

- In the dataset for the final version of the Olympus as supplied since beginning of June 2017 some MATLAB scripts are found. Do these have any meaning and supposed to be used? These MATLAB files have no relevance so please ignore them and any information that may exist in them.

- In the well control part, I was wondering whether there is a condition that FLPR can exceed 14000 m3/day, since the only drive mechanism is water injection through 7 wells, and if we are injection with the maximum rate of 1600 m3/day, it will be unlikely to violate the maximum production rate. Is that right? The FLPR is a constraint and it cannot be violated though it is difficult to violate it. There do exists strategies that violate it which will not considered to be optimal.

- For the second part, in order to have n vertical wells with dissimilar coordinates, do we need to have n platforms or can we have a Kick-off near surface to get to the desire coordinates and have a second KOP to make the well vertical? In the problem statement we have specified the number of wells possible from a single platform. If you treat each well having its own platform then the platform costs need to be incorporated as well accordingly. You can certainly have a step-out and then drill vertically once you are in the reservoir. Note: the dogleg defines what is feasible to be drilled and lift tables should reflect the trajectory accurately.

- In the NPV formula in PDF, do we need to have

, given Qs are cumulative? Indeed if you take cumulative volumes you don’t need the Dt in the formula, we will update the document and inform other participants about the change.

, given Qs are cumulative? Indeed if you take cumulative volumes you don’t need the Dt in the formula, we will update the document and inform other participants about the change.

- I notice that for all the injector wells and for 4 producer wells in the final version of the Olympus model, we don't have anymore the values related to the -Transmissibility factor; -Effective Kh; -Pressure equivalent radius ro, etc. The wells which do not have any information on the transmissibility factor etc. are all vertical wells. In ECLIPSE it is fine for the simulator to internally calculate these values for vertical wells. For horizontal wells it becomes more tricky and hence we supply the value for horizontal wells.

- In the initial February 2017 version of the Olympus model, all well files had COMPDAT fully defined (i.e., all transmissibilities for CF’s (arg #8) and Effective kh (arg #10)). These are, of course, all grid-specific. However, in the final June 2017 version of the Olympus model only some wells have these properties defined, while others are wild-carded (where in the earlier version they were defined). Yes, there are differences between these versions of the Olympus model 2. Firstly all participants must only use the final June 2017 version, so the version of February 2017 is null and void. The difference between the two versions is that the location and type of some of the wells have been changed. Any and all changes are wells which are vertical and defined by grid block number. To the best of our knowledge for vertical wells (all are grid centered) ECLIPSE correctly uses the Peaceman equation to calculate the default connection factors and hence this was not provided. If this is untrue please do let us know. The horizontal/deviated wells which were not modified/changed/updated have the connection factors provided for the different grids because the wells are not always grid centered and then (again to the best of our knowledge) the ECLIPSE default calculation of connection factors may not be always representative.

Since the well locations are fixed for the well control problem I do not see any reason why this mixed configuration of connection factors should cause any issue. Participants only have to find an optimal strategy of rates or pressures and should not change the connection transmissibility factors when working with the well control problem. For the field development optimization problem the participants do not (we certainly hope they don’t) need to use the well configuration or wells provided but rather find their own optimal trajectories and use the appropriate connection factors.

- In NPV the period for discounting is 365 days. Does this mean we need to apply discounting just ONCE per year or could we apply discounting, say, daily? As stated in the problem statement document the discounting should be calculated each month.

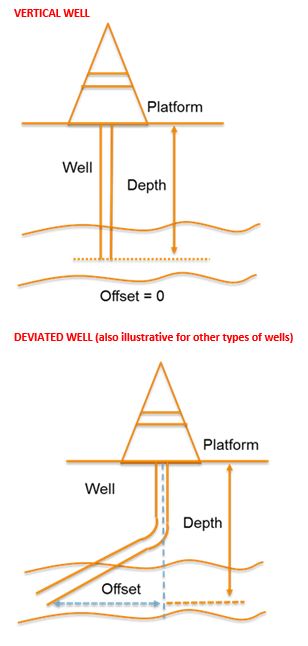

- Wat is exactly meant by “kick-off point” in the problem statement document. Several might say kick-off location is a single rig location and others might say it is by well. Where it is stated “kick-off location”, one should read “platform location” and no (drilling) rig location has to be accounted for. Please know that one may have more than one platform location. The problem statement document will be updated for this and other participants will be notified. Referring to the equation for the drilling time calculation in this document, the two images below for a vertical and deviated well hopefully explains the depth and horizontal offset that needs to be taken for this equation.